Alumina Ceramic Dental Implants – Properties, Indications and Preparation Design Considerations

Alumina ceramic material has rapidly gained a foothold in dentistry due to its excellent clinical performance, being used for fixed prostheses. This article delves deeper into its properties, indications, preparation design considerations and use.

Alumina is an extremely hard-wearing technical ceramic, known for its mechanical strength, chemical stability and biocompatibility. These properties improve with increasing purity levels; production involves dry pressing a powder using hydraulic or mechanical presses; subsequent to formation it must then be fired to give density.

Hardness

Alumina is an extremely tough and resilient ceramic with a Mohs hardness of 9, offering superior wear resistance, making it the ideal material for use in cutting tools, drawing dies, extrusion dies, molding nozzles and electrical insulation. Furthermore, Alumina exhibits excellent chemical resistance as it’s suitable for acid and alkaline environments while higher purity grades offer increased corrosion resistance.

Corrosion of alumina depends on its mineral structure and impurity content, with impurities deposited during firing causing preferential corrosion at grain boundary areas of ceramic alumina materials. Further speeding up this damage are high concentrations of acids or alkaline solutions; to increase corrosion resistance of these ceramics the amount of silica, mullite and corundum phases should increase accordingly.

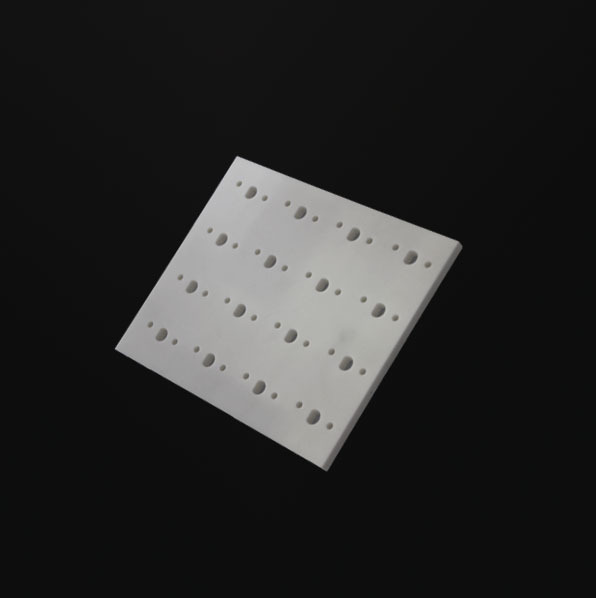

Manufacturers can create an alumina ceramic product with precise dimensional accuracy by employing various grinding and sintering processes. Alumina powder granules are compressed using dry or cold isostatic pressing methods, before being sintered using controlled chemistry to produce their final form – or alternatively injection molding can produce it instead.

Alumina ceramic is an advanced technical ceramic with many desirable properties such as high temperature stability, hardness and wear resistance, biocompatibility and inertness that makes it suitable for numerous applications including pressure sensors, fluid flow measurement devices, electron tube components for laser components and X-ray equipment. Alumina can also be used to produce ceramic-to-metal feedthroughs as well as special crucibles used in metallurgical heat treatment processes; its strength, toughness and abrasion resistance qualities making this material particularly suitable for bullet proof armor applications.

Corrosion Resistance

Alumina ceramic has high corrosion resistance and is often used in industrial equipment that must withstand exposure to various substances. Alumina ceramic can also be found in dental and orthopedic implants due to its biocompatibility and mechanical strength; fabrication methods include dry pressing, isostatic pressing, tape casting, extruding and injection molding.

Alumina ceramics’ thermal stability depends on their coefficient of thermal expansion, which determines how it expands or contracts when heated or cooled, making alumina an ideal material for applications requiring constant temperature changes. However, its stability may be altered depending on its size and shape of production – for instance if made into large blocks with narrow openings which close upon cooling could lead to cracking or warping issues as material cools further.

Grain size has also been found to significantly impact alumina ceramic wear resistance. Studies revealed that ceramics with smaller grain sizes had better wear resistance properties due to reduced frictional forces between grains due to having lower contact areas between each one and lower contact areas – these smaller grains also likely have fewer contact points with each other and therefore produce less frictional force overall.

Alumina ceramics can be formed into many different shapes and are ideal for an array of applications. Their Mohs hardness of 9 and excellent chemical resistance make them useful in manufacturing tools and grinding wheels; additionally they’re excellent abrasive products like drawing dies, extrusion dies and bearings; while their superior strength and insulation qualities make them suitable for spark plugs, circuit shells, vacuum components and spark plugs.

Thermal Stability

Alumina ceramic has a low thermal expansion rate, making it the ideal material for high temperature applications such as those done using tungsten carbide tools. Its resistance to chemical corrosion makes it even more desirable; temperatures up to 1000 degC can be tolerated without chemical corrosion occurring, while it also offers excellent abrasion and impact resistance, making alumina ceramic an excellent choice when cutting hard material such as this.

Alumina is often utilized in medical applications due to its strength and durability. Hypoallergenic and non-toxic, alumina can be found used as bone replacement material or dental implant material – although for successful application it must have narrow grain-size distribution without porosity issues.

Multiple methods have been developed to increase desirable properties of alumina. Rutile can be added to increase fracture toughness and fatigue resistance of alumina. Furthermore, doping with lanthanum, boron or tin will enhance thermal stability of this material.

Investigated is the effect of doping with tin on mesoporous structure and chemical stability of g-alumina. Samples were prepared via powder metallurgy using various ratios of alumina oxide (A/T), then calcined at 500 degC for two hours before green compacts were produced with uniaxial pressing before being sintered at 1650 degC/2 h in an electric furnace.

The compacts were then tested for their CCS and MOR strengths, with increasing additions of tin leading to increasing mechanical strength values. This could be explained by formation of AlBO3 phase next to g-alumina during sintering; Alumina doped with tin helps maintain mesoporous structure while inhibiting transformation from g-alumina into a-alumina even at elevated temperatures.

Conductivity

Thermal conductivity is an essential property for ceramics as it enables them to transfer heat efficiently over large surface areas, such as cooking pans or electrical components. Alumina ceramics in particular excel at this application due to their high thermal conductivity and low bulk density properties.

Thermal conductivity of alumina can vary significantly based on purity level and temperature conditions, porosity levels and processing methods used. To optimize these variations and make ceramic components that perform at their best when designing them, targeted matrix designs with specific processing methods must be utilized and relevant technical data should be provided from manufacturers for reference purposes or specific tests must be conducted when designing components using this material.

Another factor affecting alumina ceramic performance is their coefficient of thermal expansion, which measures how much their size changes with temperature fluctuations. A lower coefficient indicates less stress during changes, making it suitable for medical devices and orthopedic articulating surfaces.

Alumina ceramics boast low coefficient of thermal expansion as well as high melting point and strength, making them suitable for various industrial uses, including melting/casting crucibles, ceramic-to-metal feedthroughs, X-ray component feedthroughs, high voltage bushings and high voltage bushings.

Moreover, alumina ceramics have superior wear resistance, and can be produced in various shapes to meet different applications. However, its wear rate depends on the quality of raw material used during production, so to achieve optimal results when producing these ceramics it is crucial that only high-grade raw material is selected for manufacturing purposes.

Strength

Strength is one of alumina ceramic’s primary advantages, as it enables it to withstand extreme strain and stress without breaking. Alumina ceramic’s high density enables it to resist compressive loads without being crushed, while also offering great flexural and tensile strengths, making it suitable for various applications.

Corrosion resistance is another key property of alumina ceramic. Due to its chemical composition and microstructure, corrosion rates for alumina ceramic are much lower than for metals; additionally, adding La2O3 increases corrosion resistance as this strengthens crystal structures while simultaneously decreasing acid solubility.

Alumina can serve as an economical replacement for copper in electrical equipment and instruments such as vacuum pumps, sputtering targets, electron tubes and laser components. Alumina also finds widespread application in metallurgical and chemical processing applications like feedthroughs between metals (aluminum-to-metal feedthroughs), stress relieving beads (for stress relief during welding/heat treatment), thermal insulators protecting work pieces during welding/heat treatment as well as special crucibles made of alumina.

Alumina ceramic is an excellent material to use for orthopaedic implants and medical devices because it doesn’t produce toxic or allergic responses when combined with different biological materials. Alumina ceramic can even be fabricated into prosthetic devices like total knee replacements (TKRs) made up of metal condyles articulating against UHMWPE tibial plateaus – ideal for prosthetic applications like total knee replacements (TKRs).

Alumina ceramic has outstanding thermal stability, as it does not significantly expand when exposed to temperature changes. This makes it an excellent material choice for use in high-temperature environments or applications involving thermal shock such as high-temperature furnace linings in industrial settings and military uses such as bullet proof body armour tiles.