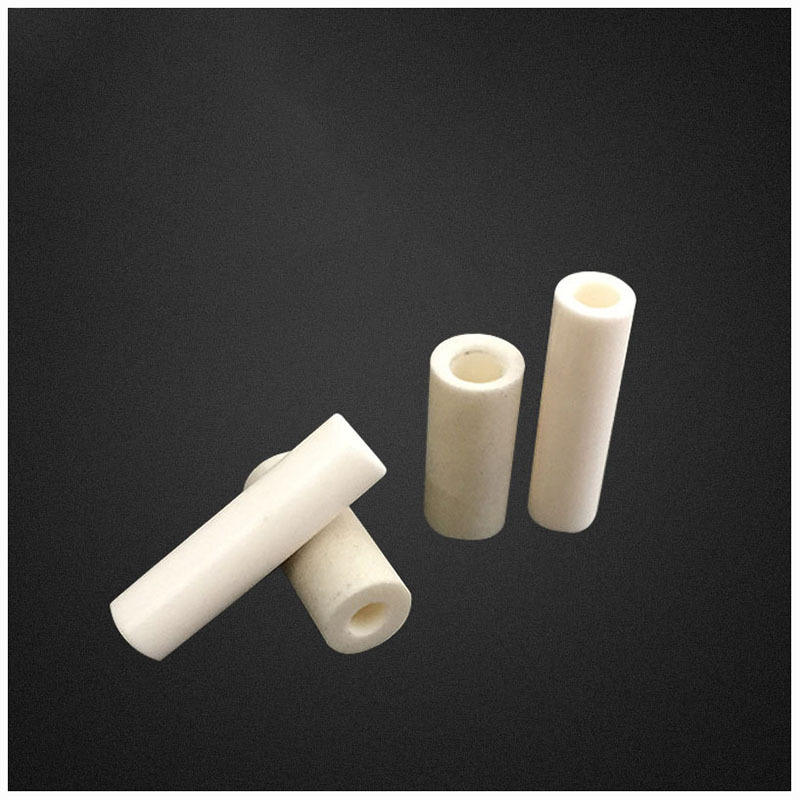

Alumina Ceramic Tube

Alumina ceramic tube exhibits excellent mechanical, chemical and thermal properties. Their dense nonporous structure offers high hardness and wear resistance as well as resisting corrosion, while possessing good dielectric properties. Furthermore, alumina ceramic tube accepts manganese metal coating for high temperature brazing assemblies while possessing great compressive and flexural strength.

Industries involved with metallurgical processes need alumina tubes for handling chemicals with high corrosion potential and to adapt their manufacturing equipment for semiconductor production. Furthermore, precise dimensions and tolerances may also be essential.

Grades

There are various grades and types of alumina ceramic tubes, each offering its own set of properties to make it perfect for specific conditions. For instance, high purity alumina tubes feature excellent plasma resistance and dielectric properties that make them suitable for semiconductor applications that demand temperature stability; additionally these dense non-porous ceramics make ideal electrical packaging or bushing material.

These ceramic tubes can withstand high temperatures while remaining chemical, wear and abrasion-resistant as well as providing good electrical insulation properties. Fabricating shapes and sizes using this material allows it to be utilized as a lining material in test electric furnaces, thermocouple tubes and corona electrodes.

94% alumina ceramics combine mechanical, thermal and electrical properties into one material that offers extreme compressive strength as well as electrical conductivity properties. They can withstand extreme compression without deforming, making it suitable for military body armor applications and suitable for mold making purposes. They’re also well suited to making ceramic-to-metal feedthroughs (X-ray component feedthroughs and high voltage bushings). Metal plating allows high temperature brazing assemblies; they’re great for pressure sensors bearing coatings electron tube components or laser components among many other uses!

High-purity alumina is highly resistant to corrosion by strong acids, alkaline solutions and hot sulfuric acid, while also being impervious to gases and liquids. However, due to being fragile material it should be handled carefully to avoid sudden impacts or shakes which may result in fractures and breakages.

Applications

Alumina tube have many applications in today’s society. From transporting liquids, gases or electrical currents through an infrastructure system to offering excellent wear resistance. Their inert composition provides excellent electrical insulation properties and protection from corrosion – as well as being capable of withstanding high temperatures without cracking under pressure.

Alumina ceramic tubes are widely utilized in industrial settings. Available in an assortment of sizes and shapes to meet various applications, alumina ceramic tubing has become an invaluable component in tube furnaces – similar to roller kilns but using tubular heating elements heated via electrical conduction instead. Alumina ceramic tubing provides durability as well as resistance against high temperatures – ideal characteristics when selecting materials for this use case.

Other industries frequently rely on alumina ceramic tubes as thermocouple protection or as insulators. Able to withstand temperatures up to 1800degC and possessing excellent chemical properties, these lightweight tubes make handling and transport simpler than ever.

Alumina tube boasts impressive tensile strength and modulus of elasticity, making them resistant to mechanical stress and pressure. Furthermore, their temperature fluctuations can be tolerated with low coefficients of thermal expansion; additionally they’re resistant to chemicals, acids, and bases making them suitable for use in harsh environments such as corrosion.

Purity

Alumina is an exceptionally pure material that stands up well to various chemical, metallurgical and thermal processes. Additionally, its chemical inertness makes it the ideal material choice for applications requiring electrical insulation and resistance against acids, bases or oxygen-containing solutions.

Alumina ceramic tubes are extremely strong, boasting an elastic modulus of up to 200 GPa and offering exceptional resistance against mechanical stress as well as high pressure and impact. Furthermore, Alumina ceramic tube materials possess superior thermal stability which enables them to withstand extreme temperatures without cracking under stress or breaking due to thermal shock damage or shockwave.

As you select an alumina ceramic grade for industrial application, be sure to consider each grade’s unique properties. Some grades offer superior abrasion resistance than others while others may boast greater electrical conductivity or thermal stability. Higher purity grades typically offer superior performance but may be more costly than lower purity versions.

Alumina ceramic tube are highly suitable for use in aerospace applications, as they can withstand extreme temperature fluctuations while protecting crucial components from radiation exposure and environmental factors. Furthermore, these tubes feature low coefficient of thermal expansion to help ensure dimensional stability as well as highly resistant corrosion protection from molten metals or glass corrosion.

Pricing

Alumina ceramic tubing has proven itself a cost-effective alternative to metals and polymers in applications requiring durable components that can withstand extreme conditions. Their exceptional durability, hardness and resistance to chemicals make them the ideal choice for processes involving mixed acids, bromine bromide halogens or any other aggressive or corrosive materials; additionally their nonconductivity protects electrical coils from damage.

Due to their superior heat temperature resistance, alumina ceramic tubes can be utilized in numerous industrial furnaces and thermal processing equipment. Furthermore, their chemical stability allows them to be utilized in protecting or reducing atmospheres; and their highly insulative qualities make them perfect for use where isolation or insulation are essential features.

Alumina tube can be utilized across many industries, such as metallurgy, steel production and ceramics production. Due to its excellent heat temperature resistance properties, Alumina tubing can also be found in tube furnaces, thermocouple protection tubes and corona electrode’s.

As alumina ceramic tube is fragile, it must be handled carefully to avoid damage or contamination. Storing it in a dry environment and regularly cleaning its outside can help extend both its life span and performance.